| Availability: | |

|---|---|

| Quantity: | |

JR Machinery

| Title | High Performance Juice Jam Syrup Stainless Steel Steam Heating Alcohol Recovery Vacuum Concentration Tank With Mixer | |

| Product Name | Vacuum Evaporator Concentrator | |

| Size | 300L-2000L | |

| Material | SS304,SS316L | |

| Heating Mode | Steam/Electric | |

| Evaporation capacity(Kg/H) | 70 - 350 | |

| Heating area(M²) | 1.2 - 4 | |

| Cooling area(M²) | 3.9 - 16 | |

| Tank configuration | Scraper Agitator | CIP cleaning ball |

| Manhole | Pressure gauge | |

| Breathing valve | Vacuum Pump | |

| Advantage | 1. Solvent recovery | |

| Processing materials | Juice, Jam, Syrup, Tomato Paste, Herbal | |

| Application | Herbal, Food industry, Etc | |

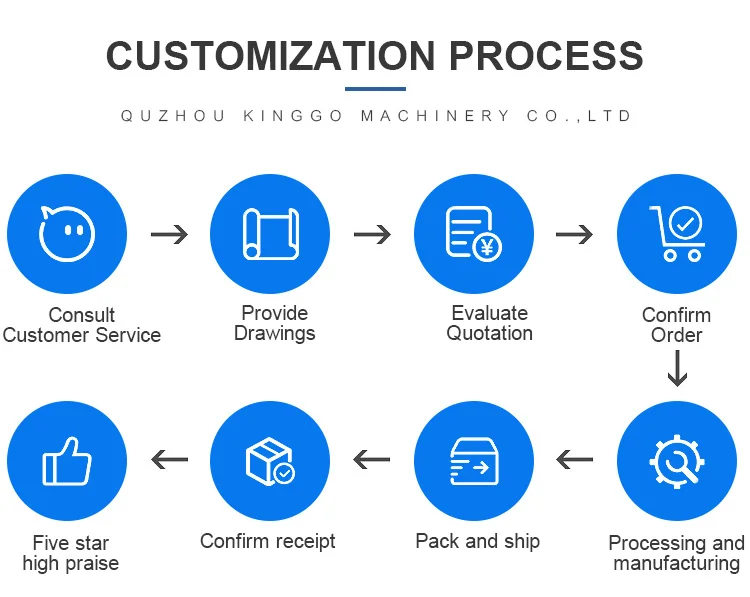

Service | Product Service | ODM, OEM,Customized according to drawing |

| Material certificate,Inspection certificate | ||

| After-sales Service | Network Support, Return And Exchange | |

| Engineer one-on-one tutoring | ||

| Shipment | By sea,as customer request | |

| Delivery Detail | Usually 10-15days after order confirmed | |

| Capacity(L) | Evaporation (Kg/H) | Heating area(M²) | Cooling area(M²) | Steam pressure | Vacuum pressure | dimension(M) | Components |

| 300 | 70 | 1.2 | 3.6 | 0.15Mpa | -0.05Mpa~-0.08Mpa | 1.9*1.1*2.3 | 1.Concentrator |

| 500 | 120 | 1.6 | 5 | 2.0*1.2*2.5 | 2.Separator | ||

| 800 | 145 | 2.3 | 5.8 | 2.1*1.3*2.5 | 3.Condenser | ||

| 1000 | 195 | 2.6 | 8.2 | 2.4*1.5*2.7 | 4.Collection tank | ||

| 1500 | 250 | 3.3 | 11 | 2.5*1.7*2.9 | 5.Vaccum pump | ||

| 2000 | 350 | 4 | 16 | 2.8*1.8*3.1 | 6.Concentrator |

| Title | High Performance Juice Jam Syrup Stainless Steel Steam Heating Alcohol Recovery Vacuum Concentration Tank With Mixer | |

| Product Name | Vacuum Evaporator Concentrator | |

| Size | 300L-2000L | |

| Material | SS304,SS316L | |

| Heating Mode | Steam/Electric | |

| Evaporation capacity(Kg/H) | 70 - 350 | |

| Heating area(M²) | 1.2 - 4 | |

| Cooling area(M²) | 3.9 - 16 | |

| Tank configuration | Scraper Agitator | CIP cleaning ball |

| Manhole | Pressure gauge | |

| Breathing valve | Vacuum Pump | |

| Advantage | 1. Solvent recovery | |

| Processing materials | Juice, Jam, Syrup, Tomato Paste, Herbal | |

| Application | Herbal, Food industry, Etc | |

Service | Product Service | ODM, OEM,Customized according to drawing |

| Material certificate,Inspection certificate | ||

| After-sales Service | Network Support, Return And Exchange | |

| Engineer one-on-one tutoring | ||

| Shipment | By sea,as customer request | |

| Delivery Detail | Usually 10-15days after order confirmed | |

| Capacity(L) | Evaporation (Kg/H) | Heating area(M²) | Cooling area(M²) | Steam pressure | Vacuum pressure | dimension(M) | Components |

| 300 | 70 | 1.2 | 3.6 | 0.15Mpa | -0.05Mpa~-0.08Mpa | 1.9*1.1*2.3 | 1.Concentrator |

| 500 | 120 | 1.6 | 5 | 2.0*1.2*2.5 | 2.Separator | ||

| 800 | 145 | 2.3 | 5.8 | 2.1*1.3*2.5 | 3.Condenser | ||

| 1000 | 195 | 2.6 | 8.2 | 2.4*1.5*2.7 | 4.Collection tank | ||

| 1500 | 250 | 3.3 | 11 | 2.5*1.7*2.9 | 5.Vaccum pump | ||

| 2000 | 350 | 4 | 16 | 2.8*1.8*3.1 | 6.Concentrator |